Description: X-ray test is a real-time non-destructive analysis to check the hardware components inside the component, mainly check the lead frame of the chip, wafer size, gold wire bonding diagram, ESD damage and holes, customers can provide good products for comparison examine.

Scope of application: metal materials and parts, plastic materials and parts, electronic components, electronic components, LED components, etc. internal cracks, foreign matter defect detection, analysis of internal displacement of BGA, circuit boards, etc.; identification of empty soldering, virtual soldering Analysis of BGA soldering defects, etc.

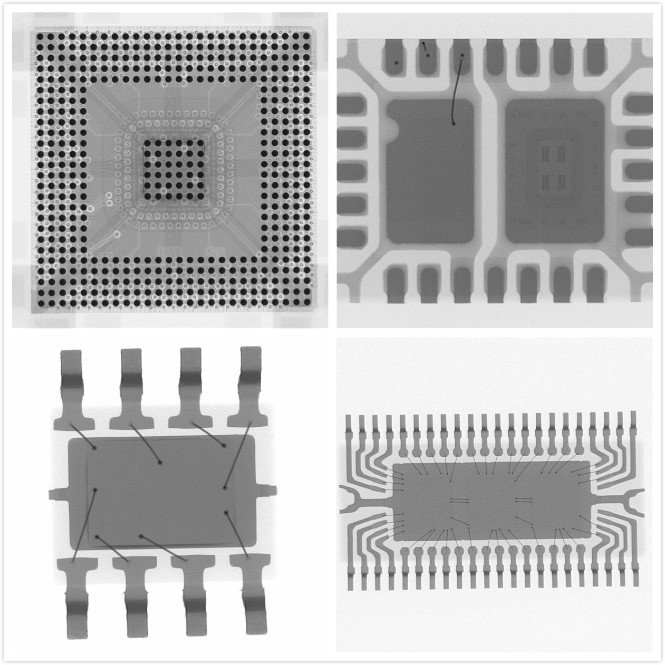

X-Ray inspection image:

X-Ray inspection equipment pictures:

Introduction to X-Ray inspection: X-ray (X-ray) detector uses low-energy X-rays to quickly detect the inspected object without damaging the inspected object.Use high voltage to strike the target to generate X-ray penetration to detect the internal structure quality of electronic components, semiconductor packaging products, and the welding quality of various types of SMT solder joints.

X-Ray inspection content:

1.Defect inspection in IC packaging, such as: layer peeling, burst, void, and integrity inspection of bonding wires;

2.Defects that may occur during the printed circuit board process, such as: poor alignment or bridging and open circuits ;

3. Detection and measurement of voids in SMT solder joints;

4. Defect inspection of open circuits, short circuits or abnormal connections that may occur in various connection lines;

5. Integrity of solder balls in solder ball array packages and chip-on-chip packages Inspection;

6. High-density plastic material cracking or metal material void inspection;

7. Chip size measurement, wire bonding arc measurement, component solder area ratio measurement.

X-Ray inspection steps:

Confirm the test location and requirements of the sample type/material → put the sample into the inspection table of the X-Ray perspective instrument for X-Ray perspective inspection → judge and analyze the picture → mark the defect type and location.

X-Ray inspection items:

1. Integrated circuit packaging process inspection: layer peeling, cracking, void and wire bonding process;

2. Printed circuit board manufacturing process inspection: welding line offset, bridging, open circuit;

3. Surface mount technology Solderability inspection: detection and measurement of solder joint voids;

4. Connection line inspection: open circuit, short circuit, abnormal or bad connection defects;

5. Integrity inspection of solder balls in solder ball array packaging and chip-on-chip packaging;

6. High Density plastic material cracking or metal material inspection;

7. Chip size measurement, wire bonding arc measurement, component solder area ratio measurement.

Learn more→Contact us→